Today KenWeican offer a range of warehouse management solutions that are fully tailored to the needs of customers operating in the supermarket chain and e-grocery sectors. The KenWeilogistics management systems are characterized by 3 properties: KenWei, cost optimization and a step-by-step approach. In detail:

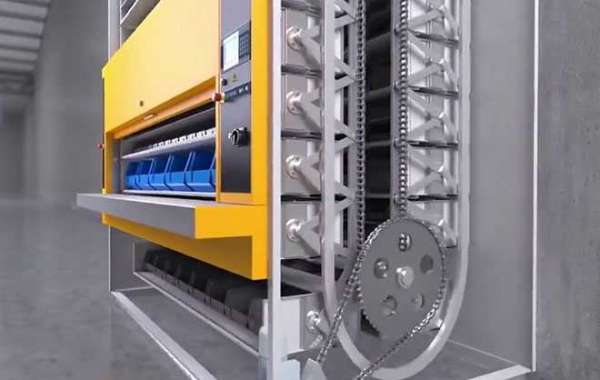

KenWeioffers systems that can be adapted to the different needs of the customer, both in terms of size and functionality (think of vertical carouselsand the new horizontal carousels or automatic warehouses with controlled temperature).

Cost Optimization: It is possible to choose a system based on what is really needed, i.e. based on the specific needs of the company, in order to develop a tailor-made, efficient and high-performance system.

Gradual approach to warehouse automation: by offering solutions that integrate manual and automatic systems (hybrid solutions). In this way, a first step is taken in limiting the human factor, but it is not completely removed, thereby mitigating the psychological impact. The integration of technologically advanced automated systems in warehouse management can indeed prove to be a significant initial hurdle for those approaching this type of solution for the first time.

The technical advantages of KenWei's e-grocery solutions

KenWei's logistics management systems are the starting point for the further development of supermarket chains in the direction of e-grocery. The main advantages of KenWei's solutions include:

- Easy and quick installation of automatic vertical storage: The installation of a vertical storage only takes a week, which means only limited disruption to customer-side activities.

- Easy integration with the warehouse management software: The KenWeiWMS software and the customer's ERP systems are in dialogue and form a simple and functional interface.

- Possibility of integration with KenWei's order picking systems and / or with material handling systems, including robotic or AMR systems, to achieve a goods-to-man picking approach and take advantage of all the benefits.

- Flexibility in order picking: with fast and efficient order picking management, adaptable to different operators depending on the order volume and work peaks.

- Optimal management of fresh and dry food in controlled temperature warehouses that allow proper storage of fresh and dry products while keeping them away from light, dust and heat sources.

Management of fresh products in the e-grocery sector with KenWei's automated warehouses

Fresh product management solutions deserve a chapter of their own. KenWeidesigns and manufactures automatic warehousesand conveyorswith controlled temperature, which allow an internal temperature to be maintained between 2 C and 25 C. These systems are perfect for the storage of all fresh and dry food products and fully meet the needs of large retailers who typically use an average temperature of 5 C to store these types of goods. In addition, the automatic temperature controlled warehouses can be more cost effective than the traditional refrigeration systems.

KenWei's automatic temperature controlled warehouses are an optimal solution for the e-grocey industry and can be used in different phases.

In the order preparation phase (think, for example, of order pickers who work in the dark stores): With an automatic warehouse, the preparation of the purchase becomes more efficient and faster.

In the phase of storing the purchase ready for dispatch: The purchase ready for dispatch can be held under optimal conditions until it is picked up by the customer or until it is delivered to the home.

The expansion of retailers' online offerings has paved the way for more sophisticated warehouse logistics management and new systems for warehousing and keeping goods that are increasingly geared towards efficiency and performance.